A strategic partner in the Automotive Industry since 1975,

About us

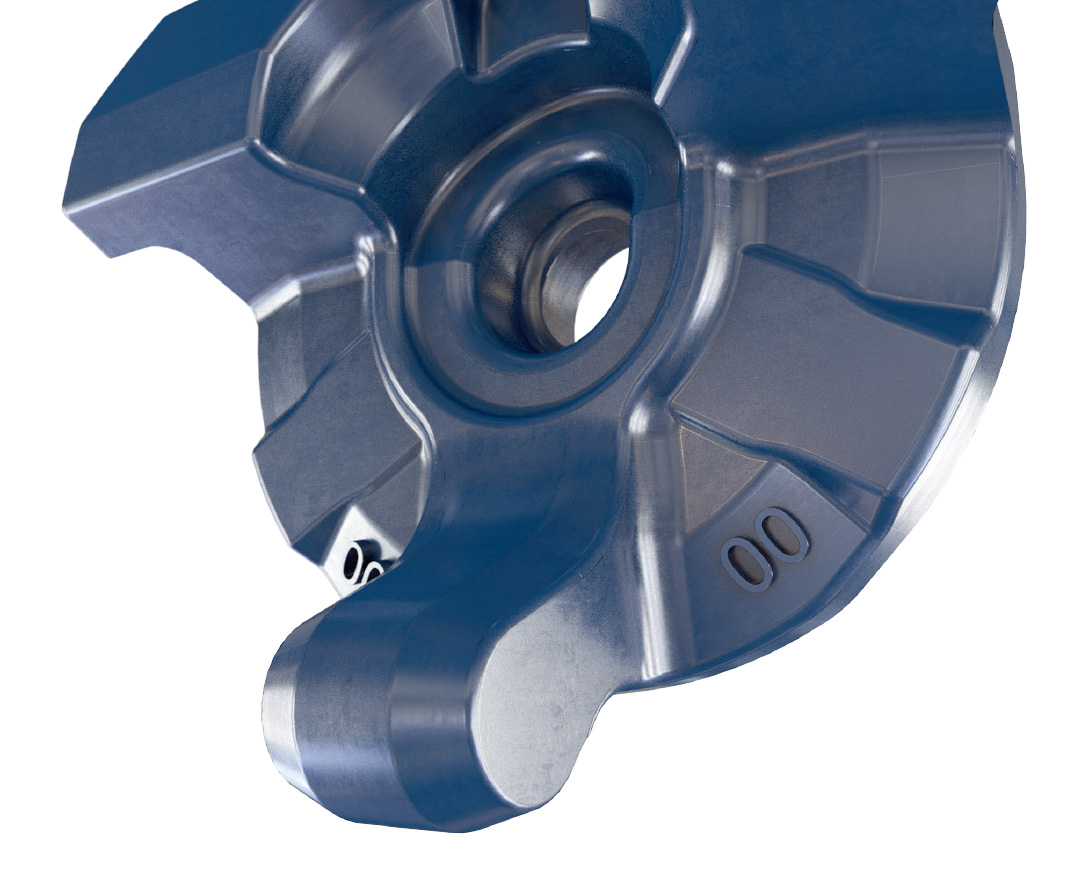

Grupo Cropu is a global supplier of Components for the automotive industry with 45 years of history. Leader in integrating different processes and technologies, offering its customers parts and ready for assemblies.